sản phẩm mớiXEM CHI TIẾT

SƠN EPOXY

SƠN HẢI ÂU

SƠN EPOXY

SƠN DẦU

SƠN NƯỚC

SƠN EPOXY

SƠN DẦU

SƠN CHỊU NHIỆT

sơn nipponXEM CHI TIẾT

sơn maxiliteXEM CHI TIẾT

sơn chịu nhiệtXEM CHI TIẾT

sơn rainbowXEM CHI TIẾT

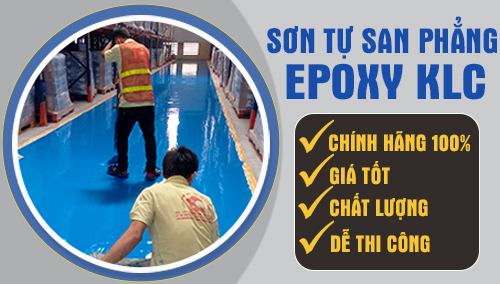

sơn klcXEM CHI TIẾT

sản phẩm chínhXEM CHI TIẾT

sơn dầuXEM CHI TIẾT

sơn jotunXEM CHI TIẾT

sơn kovaXEM CHI TIẾT

dụng cụ thi công sơnXEM CHI TIẾT

- ĐỐI VỚI CÁC MẶT HÀNG PHÂN PHỐI

Chúng tôi chuyên phân phối các dòng sản phẩm thuộc các hãng sơn chất lượng như Nanpao, Rainbow, Nippon, Seamaster, Dulux, Bạch Tuyết, KCC,…

Với phương châm xây dựng uy tín và lòng tin đối với khách hàng, Công Ty TNHH Dịch Vụ Thương Mại Xây Dựng Kim Loan chúng tôi sẽ cung cấp đầy đủ các loại giấy tờ chứng minh nguồn gốc và xuất xứ rõ ràng của các sản phẩm với cam kết cung cấp hàng chính hãng 100%…

- ĐỐI VỚI MẶT HÀNG SẢN XUẤT

Chúng tôi đã thực hiện nghiêm ngặt quy trình kiểm tra chất lượng sản phẩm và sở hữu giấy chứng nhận nhãn hiệu, giấy chứng nhận hợp quy cùng các loại phiếu thử nghiệm chất lượng sản phẩm.

Với tầm nhìn trở thành hãng sơn uy tín và chất lượng hàng đầu Việt Nam, chúng tôi đã đầu tư hệ thống nhà máy sản xuất riêng và không ngừng nghiên cứu nhằm phát triển các dòng sản phẩm sơn KLC…. Hình ảnh các loại giấy chứng nhận và phiếu thử nghiệm sản phẩm…

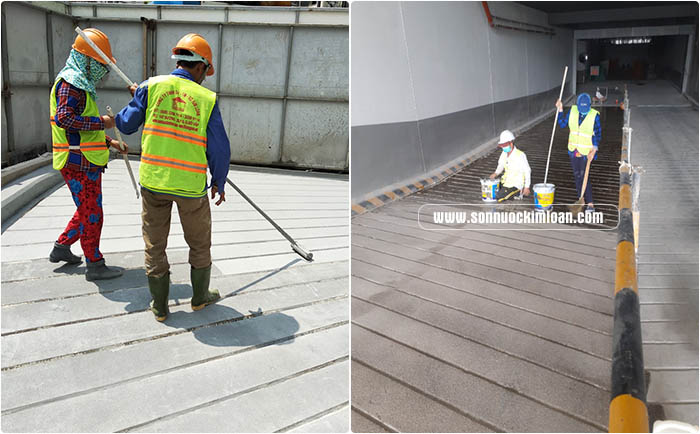

- ĐỐI VỚI DỊCH VỤ TƯ VẤN & THI CÔNG

Tư vấn miễn phí về các sản phẩm sơn do chúng tôi phân phối và sản xuất. Tiếp nhận và xử lý yêu cầu từ khách hàng trong thời gian ngắn nhất. Đảm bảo giao hàng đúng chủng loại, chuẩn xác số lượng và đúng thời gian theo yêu cầu.

Tuân theo quy trình và thực hiện tỉ mỉ từng bước thi công để mang lại chất lượng công trình tốt nhất cho khách hàng. Chịu trách nhiệm xử lý mọi trường hợp sản phẩm không đạt chất lượng do lỗi nhà sản xuất…